| Sign In | Join Free | My webtextiles.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My webtextiles.com |

|

Certification : ISO13485

MOQ : 1,00 pcs

Price : 0.5-20

Brand Name : yue lin sen

Model Number : Y06

Place of Origin : Dongguan City, Guangdong Province

Payment Terms : T/T

Supply Ability : 50000 pcs One month

Delivery Time : 5-8wofk days

Packaging Details : Vacuum packaging; cardboard box; wooden box; packaging customized according to product specifications

Model NO. : 3.1*125

Material : Steel

Feature : Disposable

Transport Package : Vacuum Packaging

Specification : 200*250*400

Trademark : yue lin sen

Origin : Dongguan, Guangdong

HS Code : 7301200000

Production Capacity : 500000

Our precision-finished stainless steel pipes are engineered for excellence in demanding industrial environments. Through a series of specialized post-processing techniques, we transform premium-grade raw tubing into high-performance components renowned for their durability, precision, and reliability.

We offer stainless steel pipes that undergo a comprehensive suite of finishing processes to meet stringent application requirements. Each step is designed to enhance both the functional and operational characteristics of the pipe.

We provide extensive customization to fulfill unique project specifications:

Primary Materials:

Standards: Materials comply with ASTM A213, A269, A312, and other relevant international standards.

| Product Category | Primary Uses & Applications | Key Technical Features & Specifications |

|---|---|---|

| Processed Stainless Steel Pipes | Chemical Processing: Transport lines for acids, solvents, and aggressive chemicals. Pharmaceutical & Bio-Tech: High-purity process piping, fermenter components. Food & Beverage: Sanitary transfer lines, brewery and dairy processing. Semiconductor: Ultra-High-Purity (UHP) gas and chemical delivery systems. Industrial Machinery: Hydraulic lines, pneumatic cylinders, structural components. | Material: 304 / 316L Stainless Steel Key Processes: Precision Expansion, Sandblasting, Scale Marking, Tapering, End Cap Processing Surface Finish: Smooth internal finish, uniform matte external finish Key Advantage: Custom-processed to ensure leak-proof connections, precise measurements, and enhanced durability for specific industrial requirements. |

Process Industries: As critical components in chemical plants, refineries, and power generation facilities.

Sanitary Applications: For systems requiring cleanability and resistance to sterilizing agents.

Measurement & Control: In level gauges, sight glasses, and sensor integration assemblies.

High-Pressure Systems: For hydraulic and pneumatic applications where secure connections are paramount.

Dongguan Yu Lin Sen Metal Technology Co., Ltd.: Has obtained theGB/T 19001-2016/ISO 9001:2015 quality system certification, as well as the GB/T42061-2022/ISO 13485:2016 medical device quality system certification. Focuses on the research and production of non-standard metal medical device precision parts, mainly as machined metal products. It possesses dozens of high-precision engra-ving lathes and CNCequipment,including CNC numerical control, numerical control centering machine, automatic lathes, turningmilling combined machines, precision laser cutting processing of stainless steel capillary tubes and stainless steel thin-walled tubes for sec-ondary processing. Main materials: stainless steel tubes, stainless steel, copper, alu-minum alloy, etc. for non-standard processing and customization. Widely applied in tools, electronics, electri-cal appliances, medical devices, automotive parts, transportation, and other industries. The company has been recognized by the industry for its "quality-oriented, honest operation" philosophy, mainly providing

non-standard part prototyping and batch production processing, supporting custom drawings and sample customization, etc. The process flow is stable and efficient, integrating industry and trade for rapid delivery, with craftsmanship spirit ensuring quality, without middlemen, excellent value for money, and the company adheres to the business philosophy of "customer first, quality first, striving for excellence, win-win coopera-tion", "Confident and reliable after-sales guarantee!!!".

It has obtained the quality system certification in accordance with GB/T 19001-2016/ISO 9001:2015, as well as the medical device quality system certification in accordance withGB/T 42061-2022/ISO13485:2016. We focus on processing and customizing products for medical device hardware, and we have dozens of preci-sion CNC lathes and precision laser cutting processing equipment. We also have a R&D team composed of senior engineers and technicians. We are committed to providing customers with high-quality and

high-precision processing and customization services for hardware parts, ensuring that each product meets the strict standards and requirements of the medical device industry. Through continuous optimization of production processes and improvement of technical levels, we can meet the diverse needs of customers and contribute to the development of the medical device industry.

|

|

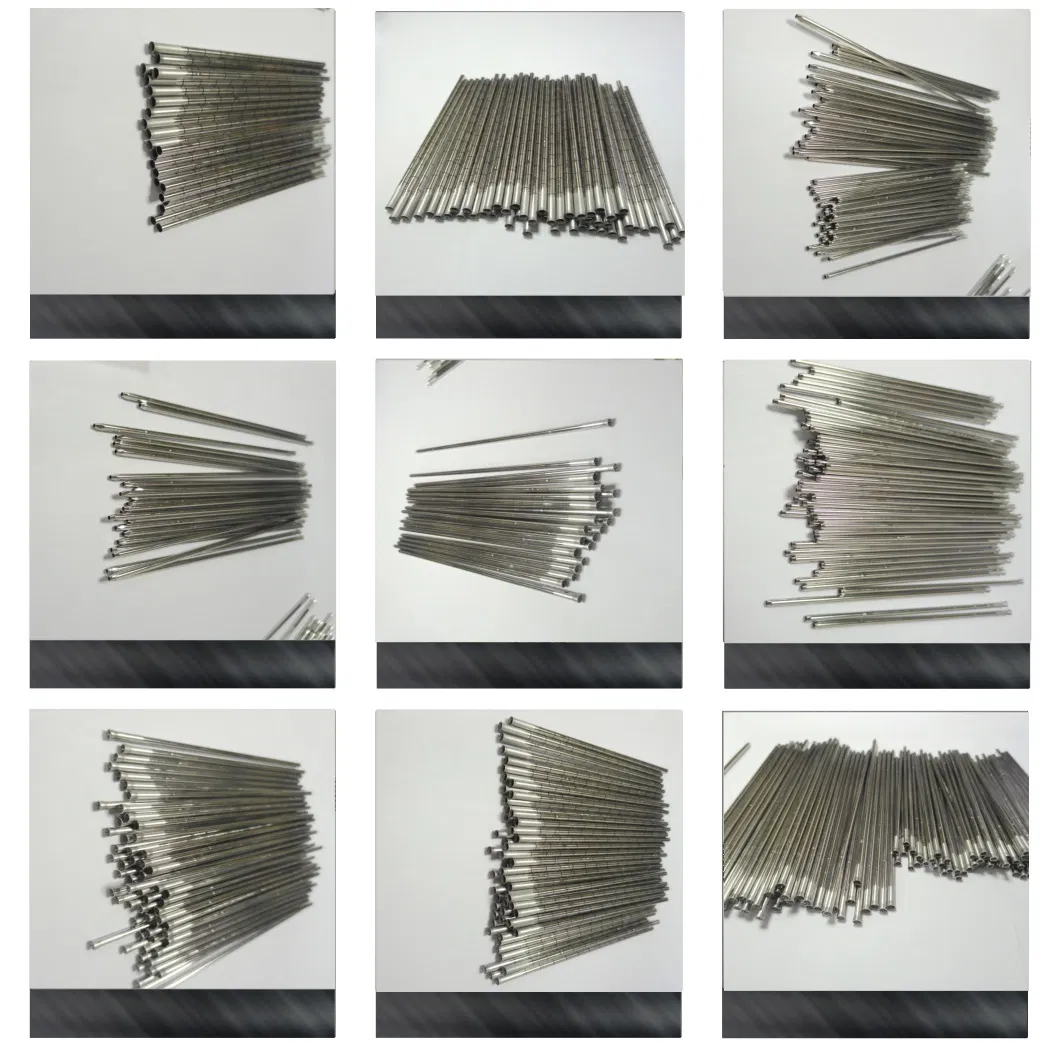

Smooth Sandblasting Finish For Stainless Steel Pipe Mouth Images |